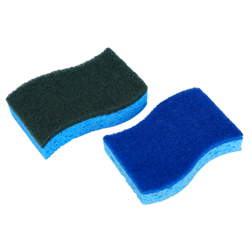

Also called mesh sponge, blasting sponge. Polyurethane filter sponge is usually processed by open-cell soft foam through net treatment. The net treatment removes the original mask or wall film between the foam networks, and obtains the main skeleton network structure. The vacancy rate of the filter sponge is as high as 97%, with excellent air permeability, superior softness and high mechanical strength

According to the aperture, it can be divided into 60PPI, 40PPI, 35PPI, 30PPI. 25PPI, 20PPI, 15PPI

Filter sponge use

Used for various motorcycles, automobile filters, filter equipment, aquariums, gas masks, air conditioners, highly breathable cushions, cushions, activated carbon filter substrates, ceramic filter substrates, etc. There is also an oil-resistant polyester filter. Slow rebound filter, etc.

Filter sponge characteristics

Fully open hole, strong pulling force, high sound absorption function and excellent penetration function. It is an ambition product for the production of air filters, oil filters, aquarium filters, etc. It is also a necessity for the production of foam ceramic filters, filter plates, filter sheets, filter nets, and can be processed into cylinders, hollows, squares, etc. according to needs The special shape is processed and formed and customized according to samples.

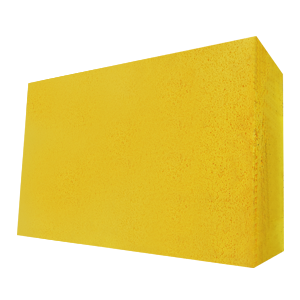

Filter sponge function

Good elasticity, strong pulling force, fast dust filtering speed, high dust filtering rate, low airflow resistance, good ventilation function, and excellent chemical functions such as drug resistance. It can be cleaned, and the effect will not deteriorate after washing. Filter cotton has good air permeability and strong mechanical strength. As a filter material, it has the characteristics of low movement resistance and high filtration efficiency. It can be washed repeatedly, and it has advantages such as economical use, environmental protection and economy.More about:CLEANING FILTER LOOFAH SPONGE SCOURER

English

English 简体中文

简体中文