Production process of hot-air non-woven fabric: Hot-air non-woven fabric can be realized by different heating methods. The bonding method and process, fiber type, carding process and fiber web structure will ultimately affect the performance and appearance of the nonwoven fabric.

Hot-roll bonding can be used for webs containing low-melting fiber or bicomponent fiber. Hot air bonding can also be used. For ordinary thermoplastic fibers and their webs mixed with non-thermoplastic fibers, hot rolling bonding can be used. When the web-forming process is the same, the thermal bonding process has an important influence on the properties of the nonwoven and determines the use of the product.

The main factors affecting the performance of hot air non-woven fabrics:

The heat carrier is hot air, which is in the bonding process. As the hot air penetrates the web, it transfers heat to the fibers, melting them and creating bonds. Therefore, the temperature, pressure, fiber heating time and cooling rate of the hot air will directly affect the performance and quality of the product.

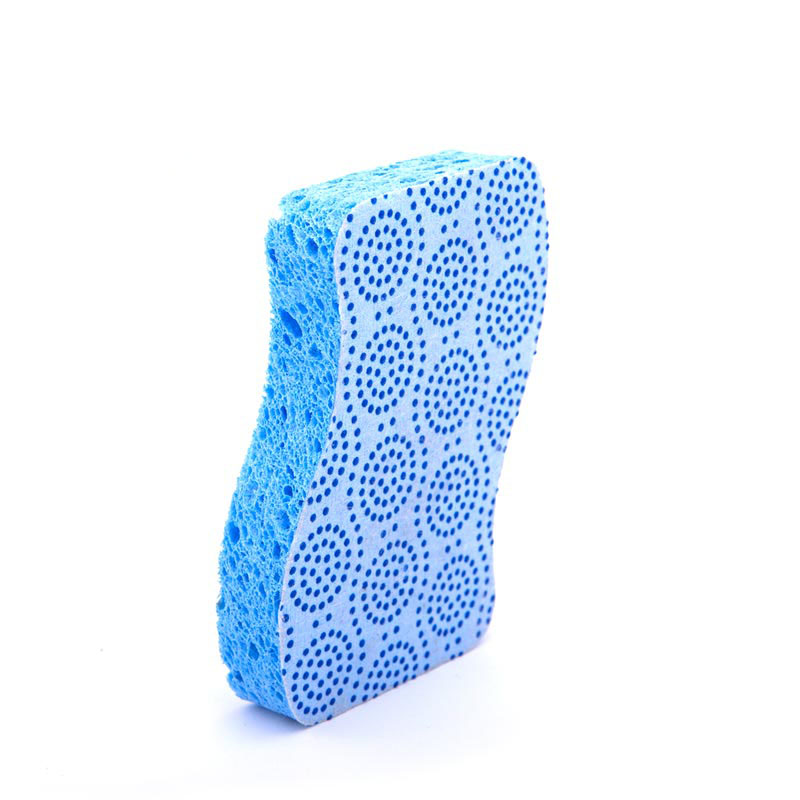

kitchen cleaning sponges wholesale

The vertical and horizontal strength of the product will increase accordingly, as the temperature of the hot air increases. However, the softness of the product decreases and the hand feel becomes harder. Table 1 shows the changes in strength and flexibility with temperature when producing 16g/m products.

The pressure should be increased accordingly, and the hot air pressure is an important parameter that affects the hot air bonding products. Generally, as the basis weight and thickness of the web increase. In order to make the hot air pass through the web smoothly, but before the web is bonded, too high pressure will destroy its original structure and cause uneven web.

There must be sufficient heating time. During production, the heating time of the web depends on the production speed. To ensure that the fiber is fully melted. When changing the production speed, the hot air temperature and air pressure must be increased accordingly to ensure the stability of the product.

English

English 简体中文

简体中文