Is polyester fiber rayon? What is the raw material of artificial cotton? Polyester fiber is the common name for polyester, not rayon. Rayon is the common name for cotton-type staple fiber. It is made of cotton short fibers spun from natural cellulose. The main varieties are cotton-type viscose staple fibers that are chemically processed and spun from natural polymer compounds such as cellulose or protein. Its specifications are similar to cotton fibers. The length is generally 35mm. The fineness is 1.5 to 2.2 dtex. It can be spun purely on a cotton spinning machine or blended with cotton or cotton-type synthetic fibers (such as polyester, nylon, etc.).

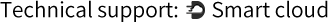

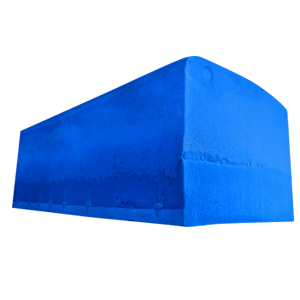

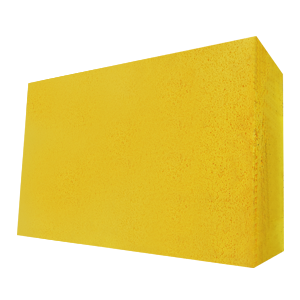

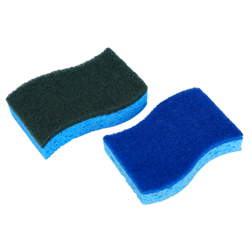

sponge wash scourer scrubber wholesale Suppliers

Polyester fiber, commonly known as "polyester". It is a synthetic fiber obtained by spinning polyester formed by polycondensation of organic dibasic acid and diol, referred to as PET fiber, which belongs to high molecular compound. Invented in 1941, it is currently the largest variety of synthetic fibers. The biggest advantage of polyester fiber is that it has good wrinkle resistance and shape retention, and has high strength and elastic recovery ability. It is durable, anti-wrinkle, non-ironing, and non-sticky.

Polyester fiber has high strength, high modulus, and low water absorption. It has a wide range of uses as civil and industrial fabrics. As a textile material, polyester staple fiber can be purely spun, and it is particularly suitable for blending with other fibers; it can be blended with natural fibers such as cotton, linen, and wool, or with other chemical staple fibers such as viscose, acetate, and polypropylene. Blended short fibers such as nitrile fiber. The cotton-like, wool-like and linen-like fabrics made of pure spinning or blending generally have the original excellent characteristics of polyester fiber, such as the fabric's wrinkle resistance and pleated retention, dimensional stability, abrasion resistance, wash and wear However, some of the original shortcomings of polyester fiber, such as static electricity in textile processing and difficulty in dyeing, poor sweat absorption and air permeability, and easy melting into cavities in case of sparks, can be mixed with hydrophilic fibers to a certain extent. Can be reduced and improved. Polyester twisted filament (DT) is mainly used to weave all kinds of silk-like fabrics. It can also be interwoven with natural fibers or chemical staple fiber yarns, and it can also be interwoven with silk or other chemical fiber filaments. This interwoven fabric maintains the uniqueness of polyester. Series advantages.

English

English 简体中文

简体中文