Can compression sponges be widely used in life:

Sponge polyurethane soft foam rubber, polyurethane material is the most common fiber material in daily life, widely used in making various "sponge" products. And its shock-absorbing, anti-friction ductile raw materials for main uses, such as shoe uppers, crawler backings for large tractor tanks. The production process mixes polyurethane foamed epoxy resin, polyurethane foam modifier and binder epoxy resin (to make the finished product with adhesiveness).

For polyurethane foam production and processing. Mix 80 parts of butadiene vinyl acetate (EVA), 20 parts of APAOPT3385, 20 parts of formamide diformamide, 19 parts of CaCO, and 0.6 parts of dicumyl peroxide, and place them in the polyurethane Foam, and use mechanical equipment to defeat the omentum sac, you can make a foam sponge. The relative density (d) is 0.028 g/cm, and the 25% reduction strength is 1.9 KPa. Polyurethane itself is non-toxic, but there are many toxic substances in the vapor caused by its ignition, and many of them will cause suffocation and death.

① The single unit that produces PU is a harmful compound, and PU is a convergent substance, and a perfect sponge product is non-toxic.

② Some PU commodities are harmful because they have a low degree of polymerization and a small amount of individual residues in sponge commodities.

③If the sponge product you bought does not have a pungent taste, it means that the foundation is non-toxic, otherwise it will be harmful.

④Slightly toxic sponge products are heated and ripened to solve. After evaporation, the foundation is non-toxic. When purchasing sponges, be sure to choose carefully to prevent harmful sponge products from being reached: very much sponge pads, small sponge toys, and sponge snack boxes, which are very easy to hurt the physical and mental health of ourselves and their children.

The main purpose of compression sponge:

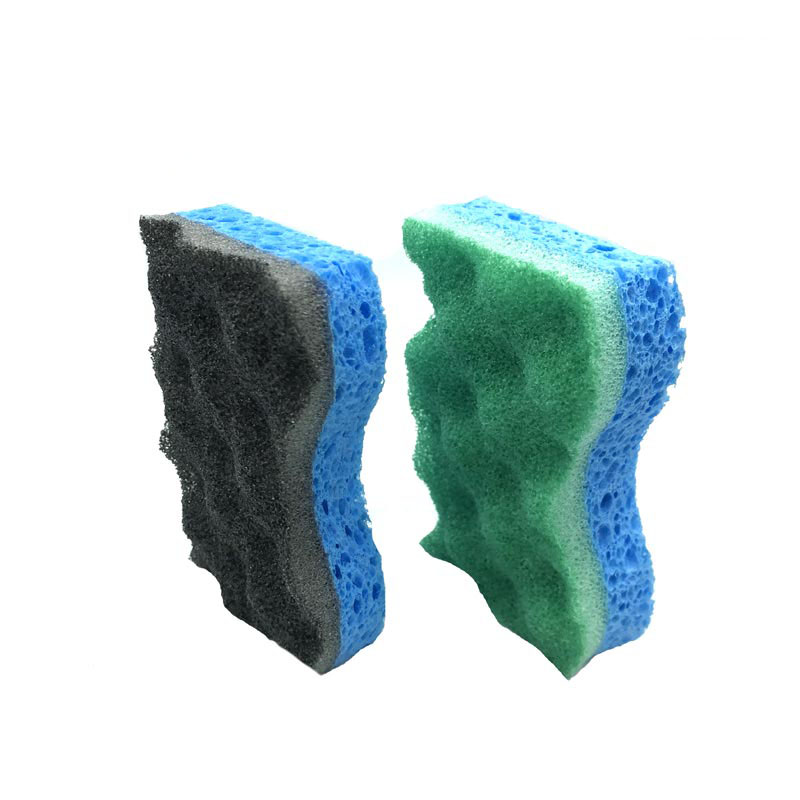

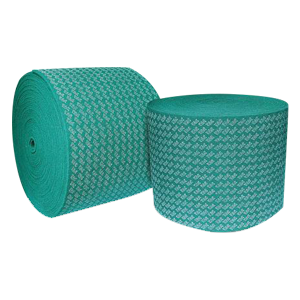

Compressed sponge is also called shrinking sponge, which is called high-pressure compressed sponge, which is a key kind of sponge. It is mainly synthesized by foreign imported equipment at high temperature. Its wear resistance is very good, the tensile strength is relatively large, the hardness is relatively moderate, and the relative density is high.

Where is the main application of compressed sponge:

① Compressed sponge can be used in home accessories, and it is mainly made into high fever compressed foam pillow core and used in cervical spine pillows. In addition, mattresses, backrests and fabric sofas and other commodity levels, high fever compressed sponges also have Very common use, because the relative price of this type of compressed sponge is much higher, so it is not universal to use high-fibre compressed sponge to make household furniture products in China, but with the increasing level of economic development in China The higher the height, the more popular these types of high-pressure compressed sponges will become.

②Printer consumables, printing pads, mobile phones, earphones, electronic devices, mobile phones, high-end compression sponges and makeup compression sponges are all the key main uses. Its engine compression ratio can be adjusted in accordance with the regulations, and the proportion of customers can be reduced according to the regulations In order to cut and match the thin and thick products, we will use it to produce and process a large number of commodities in industrial production.

English

English 简体中文

简体中文