Everyone knows that stone refurbishment, care, crystallization, and polishing are all done through media tools, which are the familiar synthetic fiber mats and steel wool.

Steel wool, of which steel wool is used on marble and soft granite, steel wool is mainly used for granite surface polishing. The surface of the stone should be smoothed before use, then steel wool and wax can be used for polishing. When steel wool moves on the surface of the stone, it can heat the surface of the stone, and at the same time, the wax water penetrates into the pores of the stone to fill these gaps and make the surface bright. After polishing with steel wool, the surface gloss of the stone can be increased by 5-10 degrees, which can be used with various refurbishing machines.

These media tools (steel wool) cooperate with the machine at a certain speed and pressure, under the action of the crystallization agent or polishing material under physical conditions, the thermoplastic material reaches the softening point or melting point under the temperature condition, and the machine force enables the material to stretch the film. The bright surface is formed, and it has become the crystal surface that everyone knew before. However, under the acid hydration of steel wool, iron ions fall on the stone, and rust and yellowing are also inevitable vicious cycles. It is also an inevitable regret that the sharp steel wool leaves a pattern on the crystal surface.

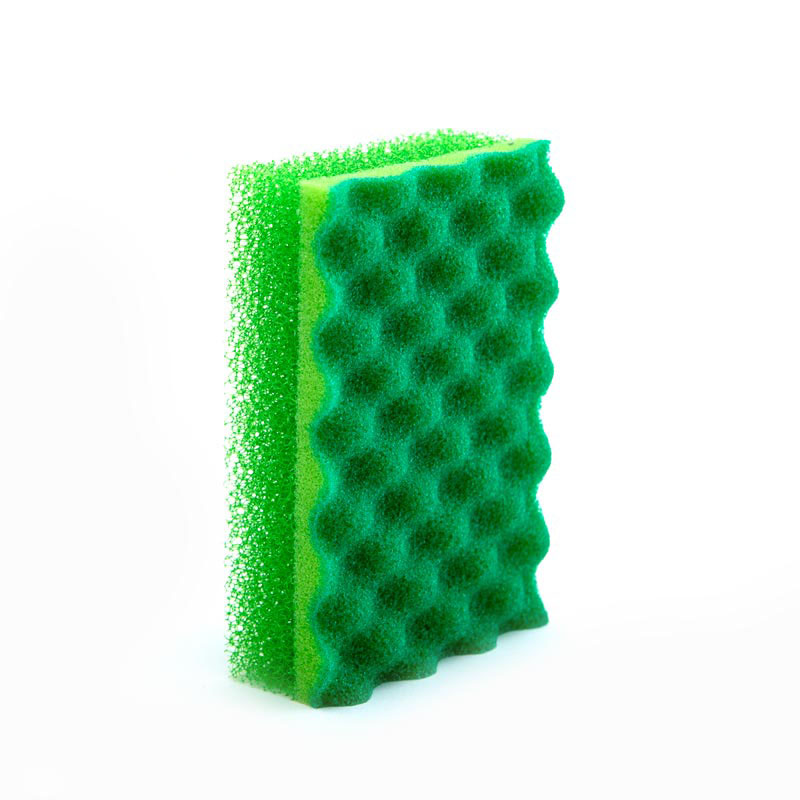

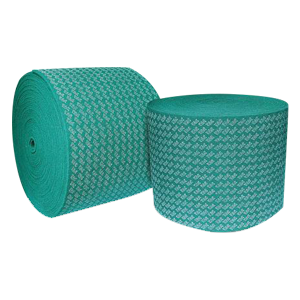

Another medium tool (synthetic fiber mat) cooperates with the machine at a certain speed and pressure, under the action of physical and chemical conditions of crystallization agent or polishing material, the molecules in the non-thermoplastic material will collide violently to form a film. . And just like this film-forming structure, the hardness, abrasion resistance, weather resistance, washing resistance, gloss retention, and air permeability of the coating film formed by it are far better than those formed under thermoplastic conditions. Moreover, rusty and yellowing lesions are greatly avoided, and the transparent mirror surface is purified. This is also a medium tool worthy of our reference and the use of thermoplastic and non-thermoplastic materials.More:abrasive scouring pads

English

English 简体中文

简体中文